L and J Fireplaces

Visit Our Store for Our Full Range

Best Prices Everytime.

Call To Our Showroom Today!

Chimney Relining

Thermosetting lining system for solid fuel and all flue types

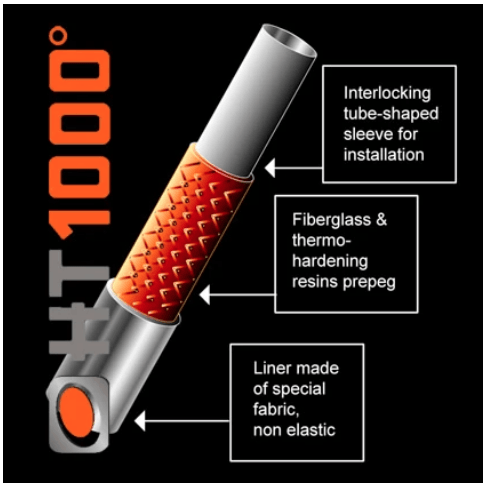

HT1000° is the only revolutionary thermo-hardening sheath with high technological content, specially built for the renovation of smoke ducts supporting continuous temperatures of up to 1000°C, like those in fireplaces, wood stoves and industrial furnaces.

HT1000° is slipped into the duct to be renovated and it is then inflated with hot air and steam to perfectly adapt to the duct walls like a second skin that can repair and seal even the smallest crack. This is why HT1000°, by perfectly adhering to the duct walls, creates an internal new layer which is completely waterproof and resistant to temperatures of 1000°C.

The HT1000° renovation system is the result of thorough and specialised studies, carried out at the Beca Engineering laboratories, on high-temperature resistant materials. In fact the components of the HT1000° meet technical standards both at anti-fire and ecological levels. After two levels of “crystallisation” respectively at 120°C and 250°C, the HT1000° sheath becomes resistant to temperatures of up to 1000°C in continuous use.

Standards

Complete adaptability of the existing flue system to all sections, whether it is circular, oval, triangular or rectangular in shape.

Sizes are available between 50mm – 600mm sheaths.

Suitable for high operating temperatures of 1300 ° C.

High power to fire barrier and flame propagation.

Thermal insulation

Resistance to alkali and acids.

HT1000° Advantages

The new system, because of its very special features, can be used in all situations where it is necessary to operate non-destructive renovations of conducts normally submitted to temperatures up to 1000°C. This material with high technological contents, does not suffer any damage at these temperatures, and retains its characteristics whatever the heat output. In classic wood fireplaces, the problem often is not so much the temperature of the fumes that may be around 450°C upstream. The real problem arises when accumulating soot ignites along the duct to reach temperatures close to 1000°C. In such extreme situations, it is absolutely necessary to have a completely incombustible material which is also inert at high temperatures. Beca Engineering, after long studies and experiments, managed to create a completely incombustible material capable of withstanding temperatures of these levels.

High Temperature Testing

The core of our HT1000° is composed of ceramic fabrics impregnated with very special resins, designed tested and produced also in aeronautics for employment at very high temperatures.

The HT1000 with its special features can be used in all situations where you need the non destructive curing of flue pipes at high temperatures up to 1300 ° C.

The high-tech material at these temperatures does not undergo any alteration and retains its characteristics.

Common Uses

Fireplaces

Wood-burning ovens.

Stoves Pellet Stoves.

Furnaces Industrial.

Ducts for industrial and high temperatures.

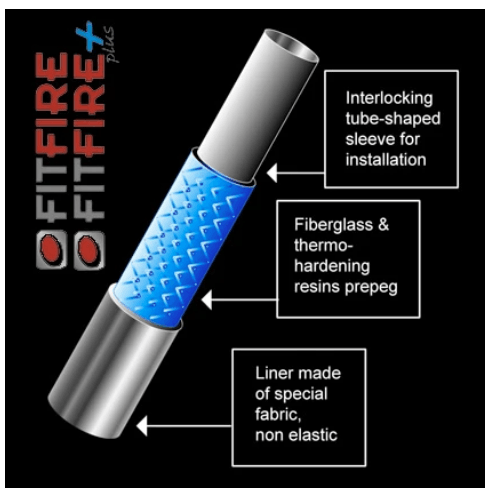

FITFIRE is a thermo-hardening sheath with a heart of fiberglass and water-based phenolic resins for gas applications

The jacket is the first of a range of four products, coming from applied research and thanks to modern and most advanced technology in the world. This is the most innovative system of renovation for all gas ducts (maximum exhaust temperature: 300°C), which combines the most intelligent materials with the most advanced research. The result is achieved through the composite of hi-tech research. In the BECA Engineering srl laboratories, near Milan, our technicians put their passions and intelligence to study and develop systems that adapt to all situations, with one goal: “Do not destroy, and thus reuse the currently existing duct”. FITFIRE meets and marries all possible shapes of your gas duct, just like a tailor-made suit, and thanks to its high-tech textile materials, it will form a highly-resistant layer which will work as a “second skin” on top, making the duct much stronger than before

FEATURES

Insulating and waterproof material: improves exhaust fume speeds; Self-standing material: no need to anchor it; Clean work: no excessive dust; Higher thickness compared to conventional materials; Higher heat resistance: tested up to 450°C; Residual internal roughness: <0.5 mm; Thermal resistance: as per UNI 9731 D; Thermal conductivity: 0,4 W/MK; Smoke speed: > 20-30%, compared to that of steel and stainless steel; Tensile strength: 400 N/mm2; Resistance to corrosion: H2SO4 conc, HNO3 conc, Hcl conc.

FITFIRE: ADVANTAGES

Installation time: paltry compared to other renovation systems (less than a day to the duct of a building)

Less destructive: no masonry required.

Simpler: it just takes connecting the devices to the duct.

Cleanliness: no rubble, therefore no formation of dust.

Waterproof insulating material: improves exhaust fume speed

Self-standing material: no need to anchor it.

No joints:the one, continuous tube is cut to measure during assembly.

Higher thickness compared to conventional materials.

Heat resistance: Continuous use at 300°C

Total resistance to condensation and corrosion

FITFIRE+

The thermosetting lining FitFire plus is now even easier to install, with higher yield and greater economic pressure to seal the moisture up to 5000 Pa.

Flues

The sheath FitFire with its features is ideal for the restoration of the flues, being resistant to high temperatures can be used for the discharge of centralised boilers, or the restoration of collective flues or device type “B” open chamber and natural draft.

The large thermal resistance combined with good thermal insulation make the sheath Thermoset FitFire an ideal product for the discharge of the combustion gases of heating appliances and hot water production, ensuring also a speed of the fumes superior to other commercially available materials.

The certification of resistance to acid condensate drains to make it suitable for high humidity condensing units newly developed.

Ducts

The sheath FitFire find easy application in the field of air conditioning. The very low residual internal roughness (less than 0.5 mm) allows the inner lining of existing pipelines without any limitation to the operation.

FitFire is tested and certified.

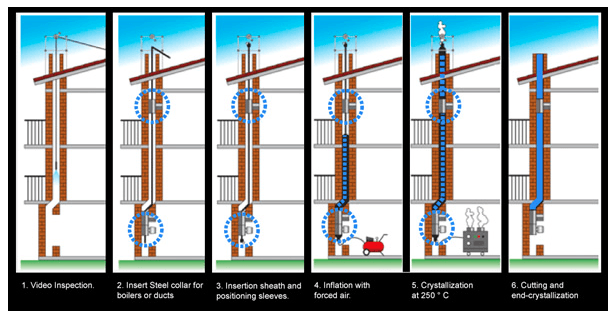

Installations

The FITFIRE sheath is slipped into the duct to be renovated. It will be inflated first with air then with steam. This will allow it to expand and fit perfectly the duct’s perimeter like a second skin. Any bumps or cracks along the duct will be sealed since FITFIRE completely adapts and adheres to the existing walls, making the duct totally waterproof and protected from condense.

Once the sheath is inserted in the chimney the thermosetting resin is “fixed” with a jet of steam at high pressure and temperature, hardening the sheath so that in a few minutes the duct is restored without the need for building works, reducing the time and cost of implementation.

No need to break walls and floors to remove old pipes.

FITFIRE Certification

Issued by Institute of Research & Tests M.MASINI S.r.l.

Designation according to UNI 1443 – UNI 1856 et 1859: Camino EN 1443 standards

Gas Leakage Test (EN 1856-2:2003 pt.6.3) R.p. n.768-2006

Resistance to fire soot test (EN 1856-2:2003 pt.6.2.1) R.p. n.768-2006.

Resistance to condensation test (EN 1856-2:2003 pt.6.4.5) R.p. n.769-2006

Thermal resistance test (EN 1856-2:2003 pt.6.4.3) R.p. n.770-2006